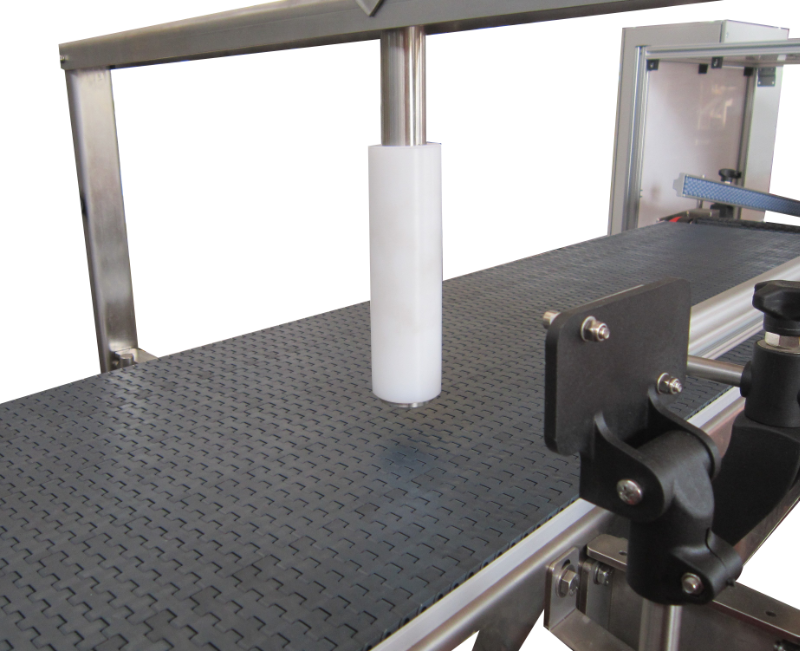

Rotation Peg

Marpatech Rotation Peg is one of the most effective accessory solutions for the rotation of products on the belt, allowing the rotation and the consecutive directing of the same to the next production phase.

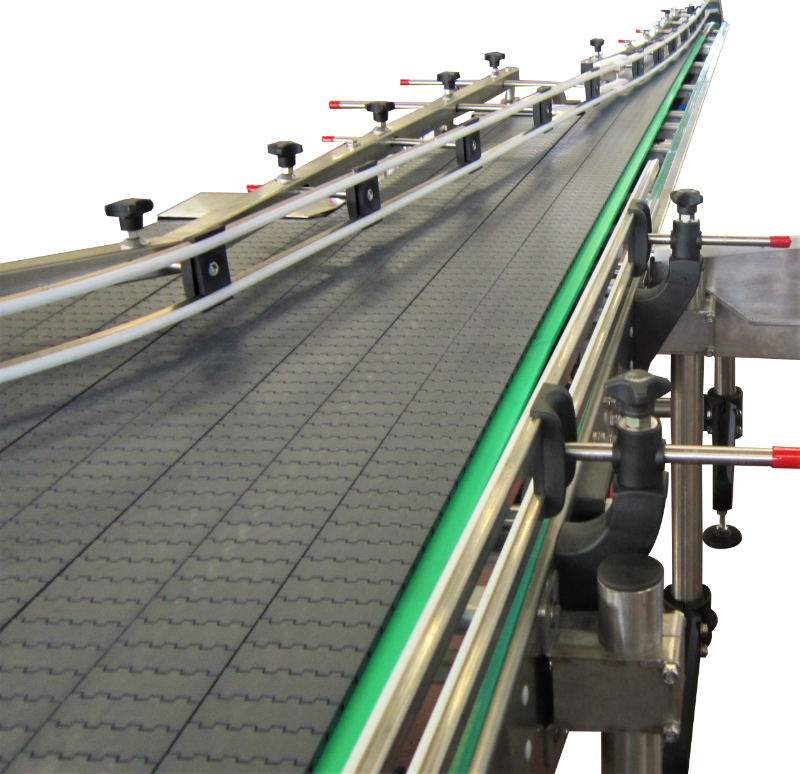

Bottle Aligner

Marpatech Bottle Aligner is designed for the bottling industry. Aligner tables can be manufactured based on customer layout and feed rates required by the line.

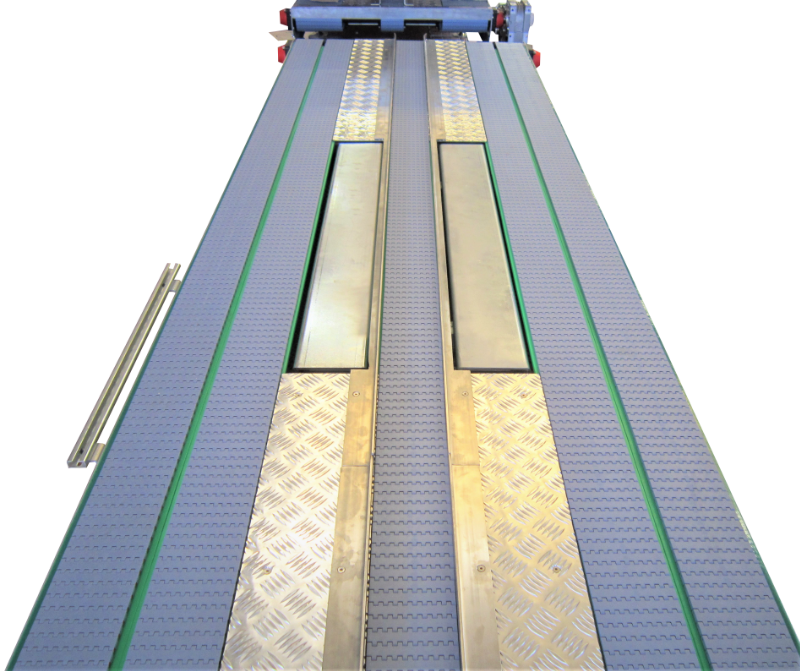

Motorized Board

Marpatech motorized board is the solution that gives the product the transversal movement and stability necessary for correct alignment with the flow, even in the case of products that are particularly difficult to transport.

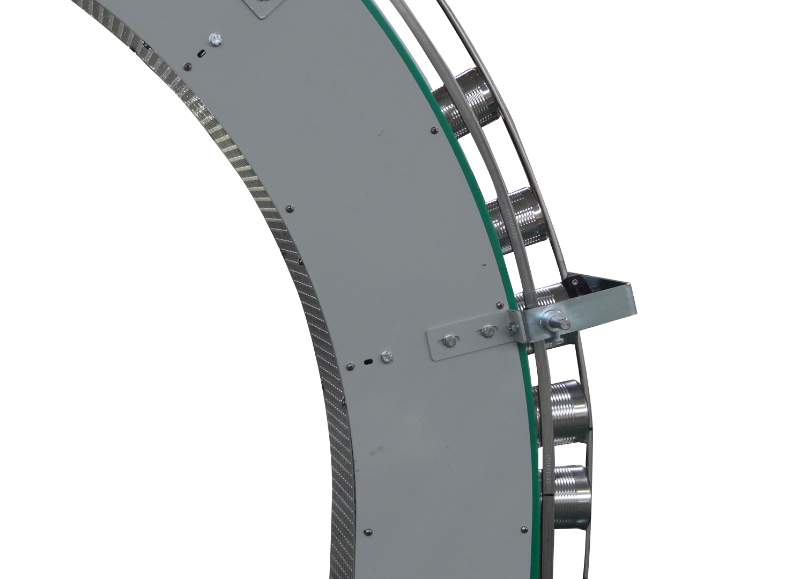

Magnetic Conveyor

The flagship of Magnoni brand, now an integral part of Lm SpA, magnetic belts are indispensable when it is necessary to lift, overturn or descend iron cans of different sizes, both empty and full.

Pan Conveyor

Marpatech pan conveyor is a very clean and essential solution for the bakery sector, possibly equipped with pushers or pneumatic stops for automated handling.

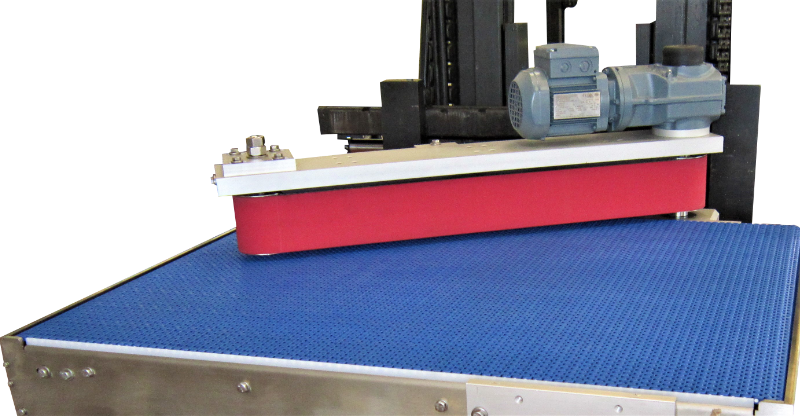

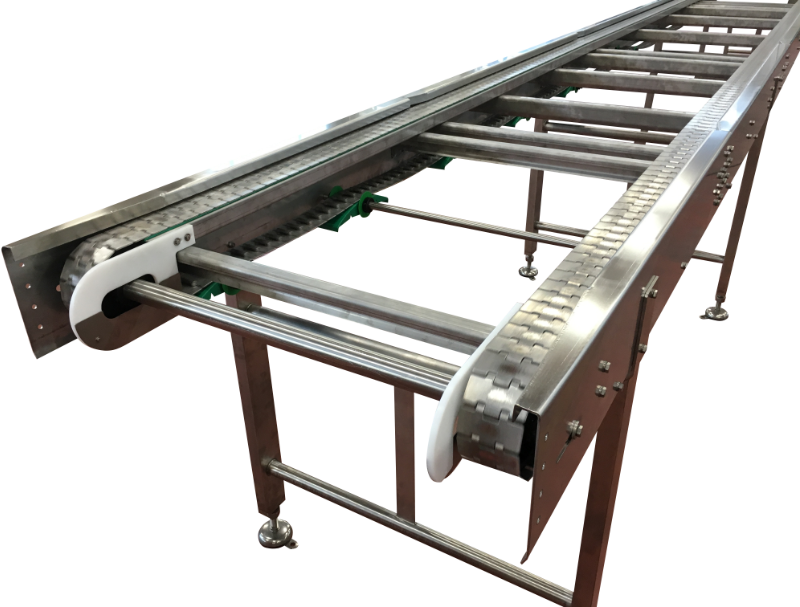

Modular

Marpatech modular belt pallet conveyor is designed to support heavy loads and ensure maximum versatility with the highest level of strength.

Fabric Conveyor Belt

Marpatech fabric conveyor belt, characterized by multiform structural solutions, meets the most competitive standards of efficiency, modularity, ease of maintenance and cleaning.

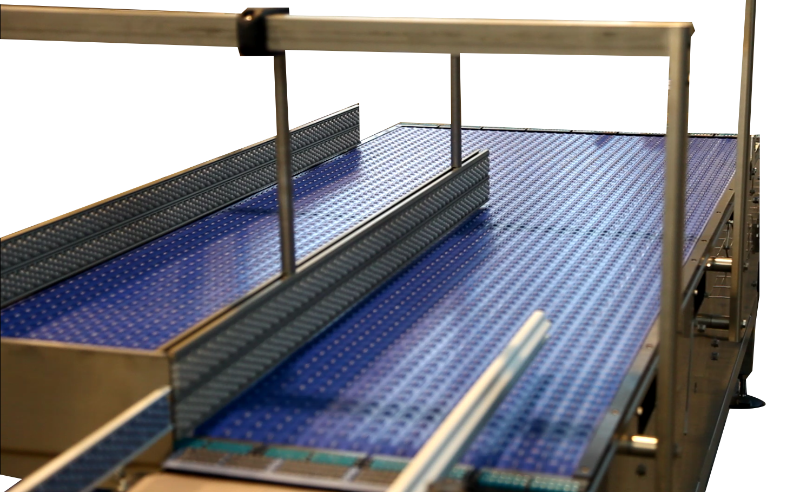

Layer Preparer

Sortech layer preparer is the most flexible and complex configuration and can be equipped with several drives to ensure the correct handling of the product in the desired position.

Reject

The Sortech reject configuration allows the product to be diverted towards a laterally installed idle roller conveyor, in case of packaging defects in the line.

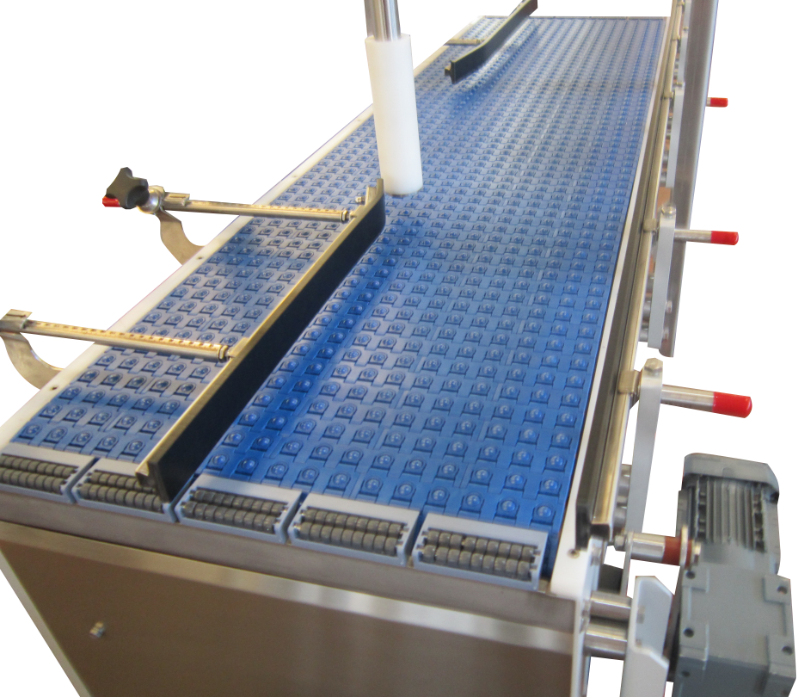

Aligner

Sortech’s Aligner configuration allows the controlled and selected alignment of the line products at right, left or center wire, setting the action to be performed for each incoming product and adjusting time and speed of alignment.